UV Ray retrofits presses with UV LED systems at Eurolabel and Skanem India

UV Ray has recently retrofitted presses at Eurolabel in Italy and Skanem India with new UV and water-cooled LED curing systems to enhance production performance and increase energy efficiency.

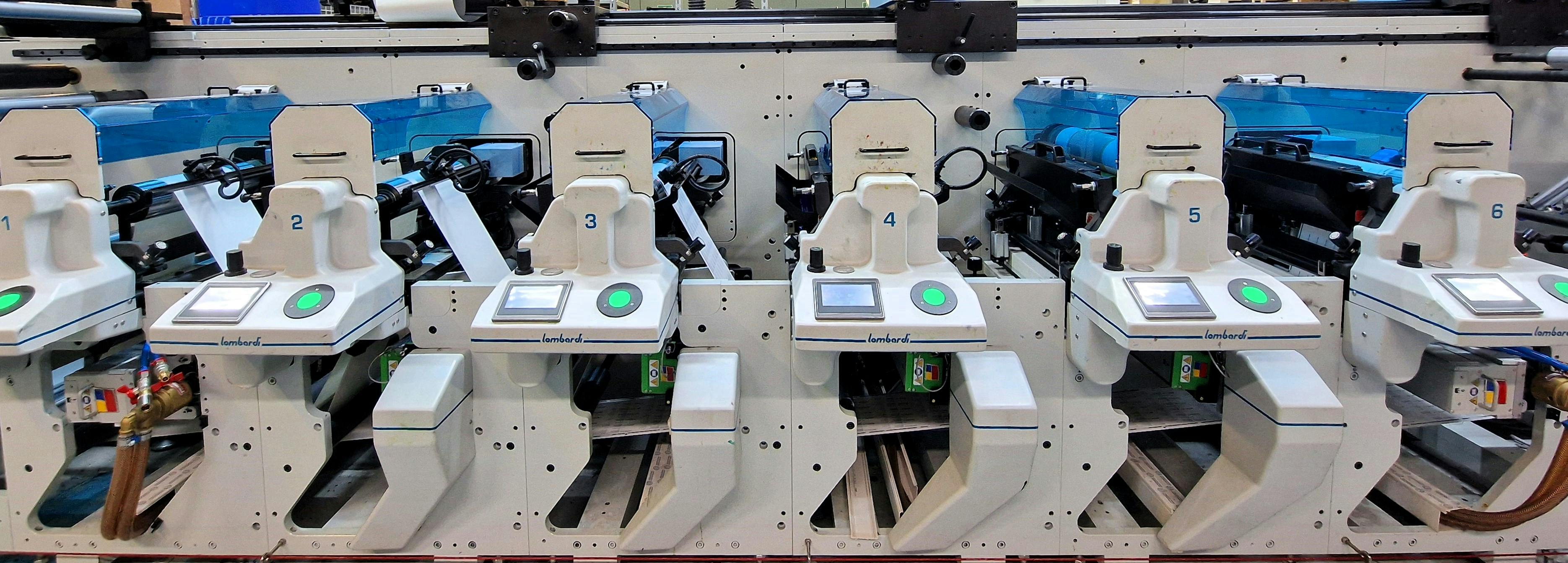

Installed on Eurolabel’s Lombardi press were UV Ray’s MaxLED curing systems on a chill drum with no extra drilling or path modification required. Overall improvements include a higher chill temperature than original (22°C compared to 15°C); no registration issues at any speed/power and with a range of substrates and colors; simple press startup with no color vibration; easier repeatability from the straightforward control panel design; no register adjustment needed from start-up to production printing speed; and stability due to water cooling of the LED and drum.

Maximum energy savings were achieved with curing using less than 20% of LED power and lower energy required from the chiller to keep the drum cooler. Spare power is available for more difficult colors to cure.

At Skanem India, their Bobst (Gidue) E-Combat 370mm press received an industry-first retrofit with UV Ray’s hybrid Atom UV and MaxLED curing systems. The retrofit was competed by Mayank Pandya of MNO Engineering and Oam Pandya of Lumen Engineering, representing UV Ray srl in India.

The hybrid LED and UV curing systems include eight LED (water-cooled) stations and two stations of conventional mercury arc UV technology (air-cooled with chill-base), all integrated into a sophisticated curing system ensuring long-term high performance and stable operation.

The advantages of an LED water-cooled system include operating at 25W/cm, stable output in any condition, low temperature transmitted to the press through the web, longer lifetime, and a sealed LED COB to avoid vapour contamination. The system has standard features such as an IR filter and quick self-restrained water plug fittings, eliminating noise from a blower as no airflow is used from the ambience. The chiller, running the chill plates/base, keeps the web cooled and consumes less power than an air-cooled unit, which typically uses the power of a blower and AC cooling.

“We take pride in our extensive track record of successful hybrid LED UV system installations on industry-leading printing presses,” said Pandya. “Our notable clientele includes Nilpeter, Monotech, Vinsak, Weigang, and AKO, demonstrating our commitment to delivering advanced and tailored solutions to a diverse range of clients.

“UV Ray srl stands at the forefront of the sustainability wave, asserting its leadership in the Indian market with a remarkable number of LED UV installations. We excel in retrofitting, demonstrating a focused commitment to upgrading existing systems and processes with cutting-edge LED and UV technology.”

Media contacts:

Stefano Maiano | UV Ray +39 0293 5660 66 s.maiano@uvray.it

Heather Roth | Heather Roth Communications +49 1522 181 3284 heather@hrothcommunications.com