Lamps or UV LEDs a matter of philosophy

[Original article from MetaPrintArt translated into English]

The choice of UV curing technology depends on production requirements and possible energy savings, but there are companies, particularly in the field of labels, for which the choice is up to the customer. It is the business philosophy that directs the decision to traditional, LED or hybrid—as Aldo Franco, director of Eurolabel explains.

The retrofit solution

We return to Eurolabel and their new plant in Lainate, intrigued by a newly installed retrofit solution on two AB Graphic Digicom series 2 and 3 finishing semi-rotary machines, with the insertion of UV LED modules from UV RAY. Aldo Franco leads us through the decision process to explain why the choice, but more importantly, how. The modules we see installed in retrofit replace the original lamps, but not for that matter permanently abandoned. As Aldo Franco explains, in some sectors, particularly in the pharmaceutical industry, before making any changes on one's equipment such as change of substrates, inks, and coatings, etc. - the customer must be informed who only after thorough testing and verification approves the changes. "This is why," he says, "in certain cases we have to have both LED drying modules and modules with traditional lamps available."

UV LED Inks

Inks change. In fact, in recent years, in order to make UV LED curing effective, manufacturers have developed new inks suitable for this technology. For routine jobs (90 percent), the two Digicoms with their flexo and screen printing units use UV inks and varnishes suitable for drying with LED modules.

Saving energy and time

Aldo Franco also explains what the advantages of this choice are, but first we ask why they turned to UV RAY, which as we can see is the first time entering Eurolabel. "This retrofit stems from the need to change the original system, and we wanted to partner with an Italian company, of which we have had excellent references from colleagues. We know their systems are reliable, and there is also the advantage of being able to count on assistance when needed."

Coming to the benefits, the one that is on the surface the most "appealing" is the energy savings, which drops consumption by 70 percent. But there are other benefits that need to be taken into account, especially when printing self-adhesive labels.

Another advantage is time savings, when considering on/off the LED has an immediate on, without the warm-up time and, equally important, it dries regardless of the speed of the web; unlike mercury lamps whose power varies with the printing speed.

Multilayer labels

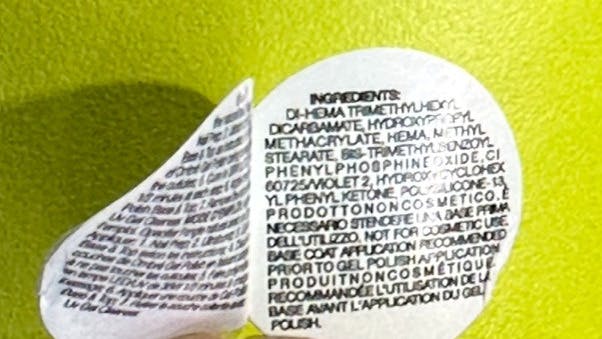

Aldo Franco then shows us a "gem." We talk about the advantage of having UV LED drying for multilayer labels. What we see are small sticker-size label booklets with QR codes when opened, containing text inside in body 4.

Given the extremely small size, both the codes and text must not be deformed by possible elongation of the material due to heat.

This is possible precisely because the LED emits cold light. Thus, traditional lamps, UV LED, or hybrid, are dependent on the needs of a complex market such as the label industry.

Today this can be done, thanks both to the modules that UV RAY has developed evolving in parallel with the evolution of the inks, and because the inks themselves allow for either technology—even hybrid—thanks to dual purpose inks.