Array, a brilliant idea that seems obvious in retrospect

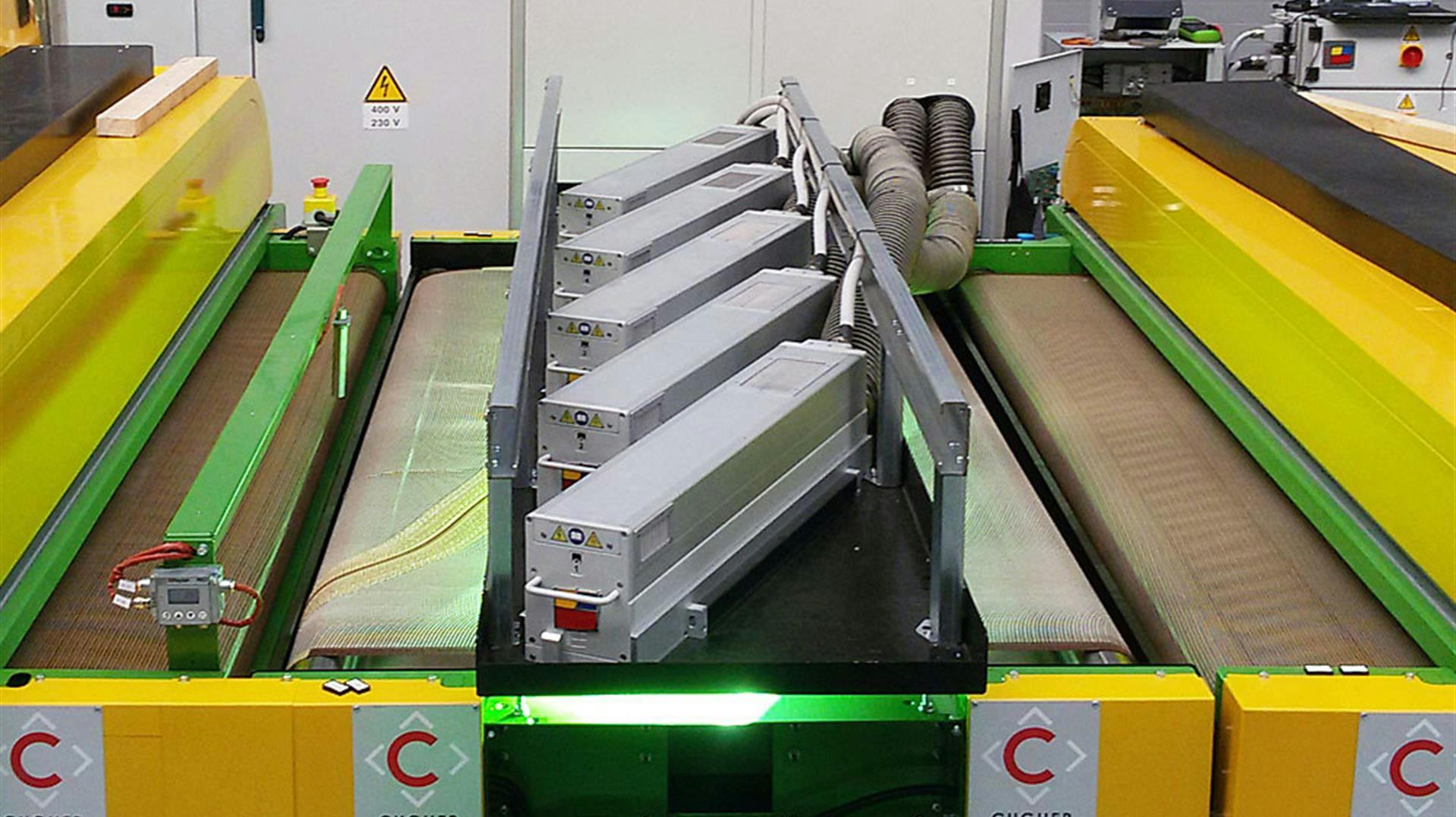

UV Ray has developed an extremely simple system that satisfies all printing width requirements: an array of reflectors, an obvious yet brilliant solution to the problem.

With the UV Ray array, size is no longer a problem thanks to its “modularity”, in other words formed by many standard units, can cover any needs and is able to solve particular or extreme applications.

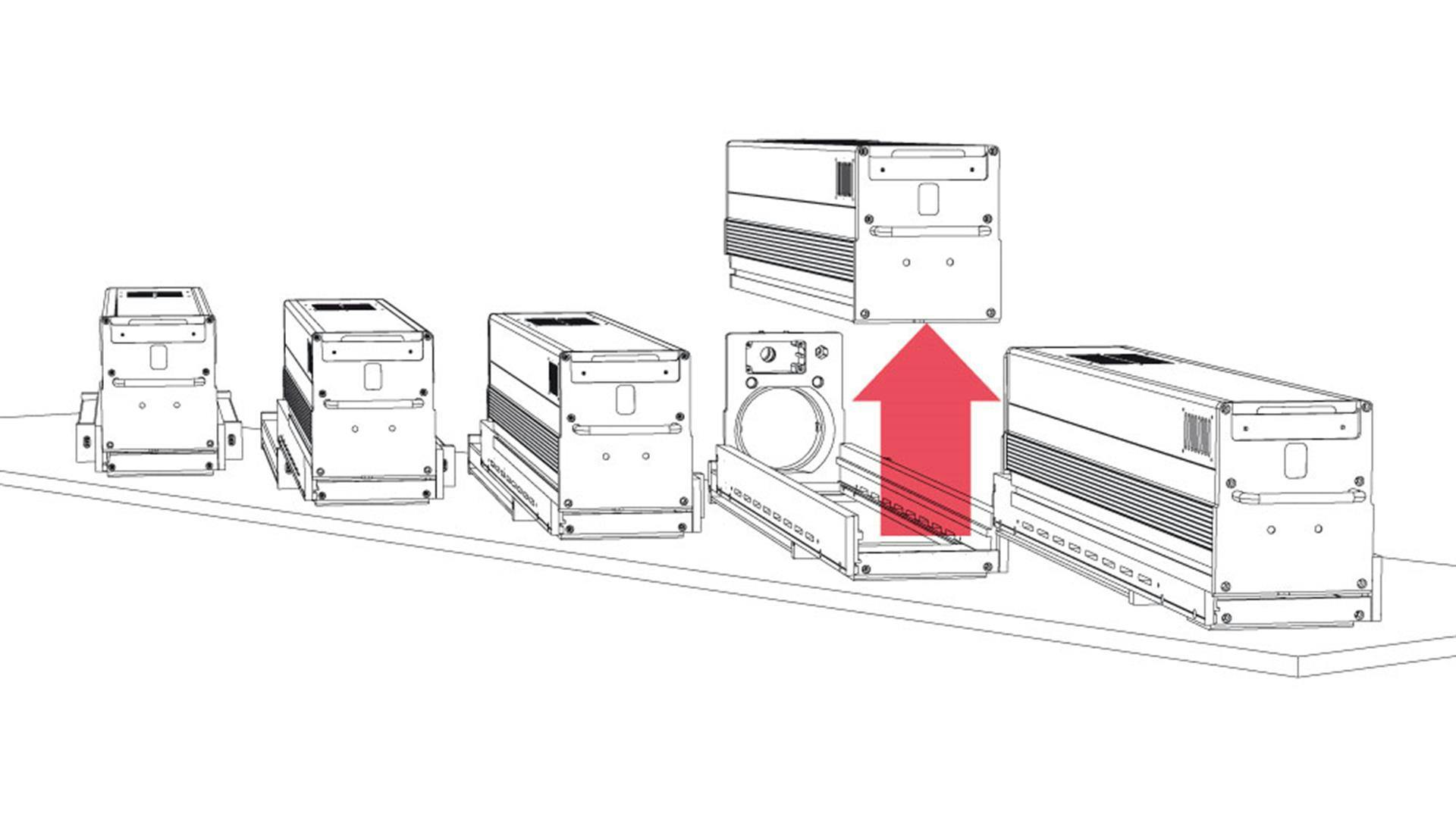

The simplicity of this solution can be seen in the photograph and the advantages, instantly inferable, are several:

TWO IMAGES

- no limits in terms of width: as many components are used as needed to reach the desired measure, with total accuracy in terms of both length and power;

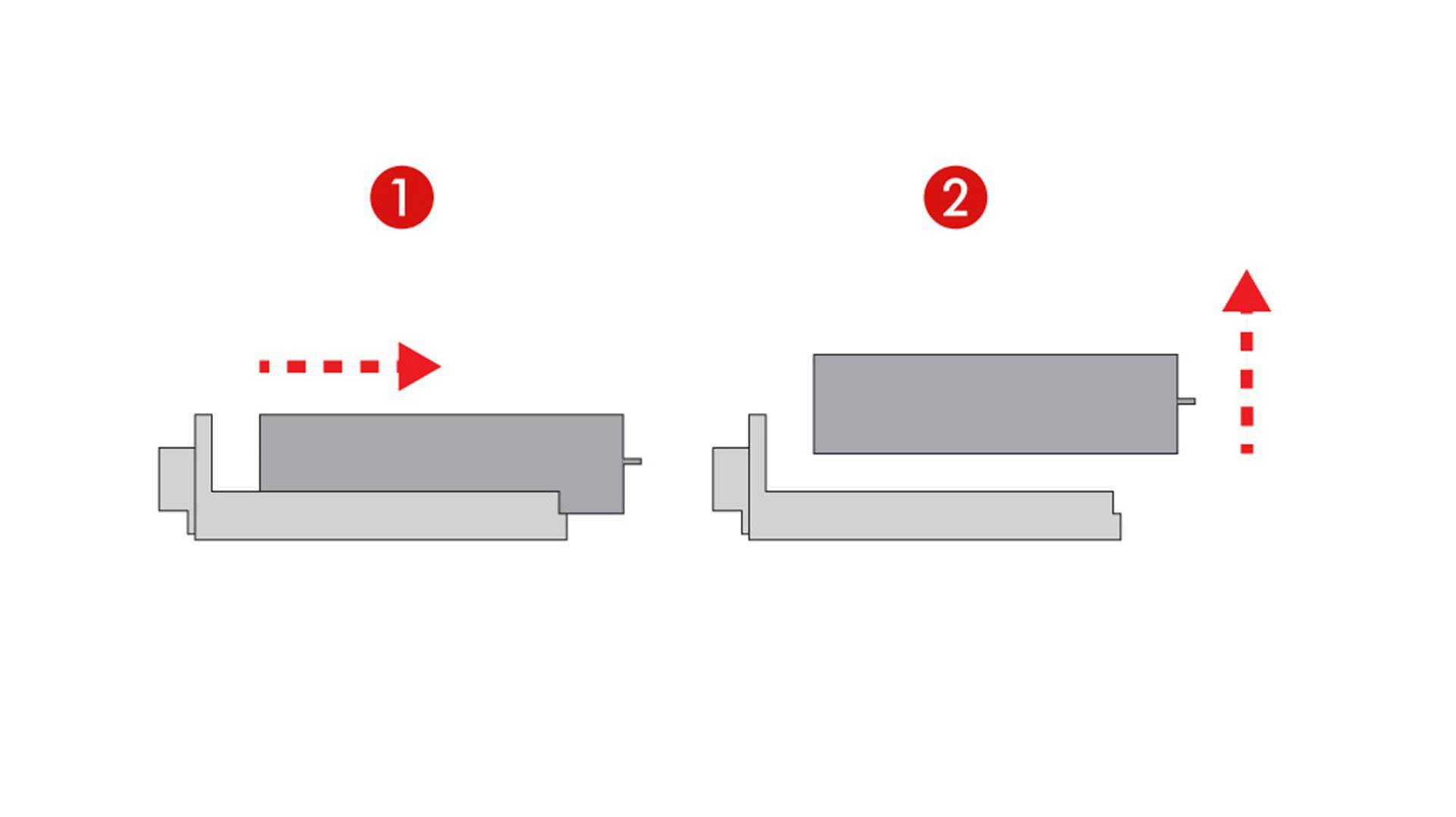

- extremely simple maintenance: simply release the lamp and remove it vertically (see fig.);

IMAGES EXTRACTION TWO GESTURES

- by switching off the side lamps, you can work on smaller measures for additional energy savings;

- the support structure is extremely simple, sturdy, and easy and quick to install. No other invasive operation or maintenance is required.

- the products are the items UV Ray has been making for more than 20 years, no ad hoc reflectors but instead the entire range available for all type, with the same quality, efficiency and reliability as always.

The competitors’ solution

A comparison with the competition shows an application made up of different reflectors with a 2,000-mm light arch overlapped so as to form a vertical wall through which the media passes.

The system, a large, complex and heavy structure, shows clear difficulties in terms of management and maintenance:

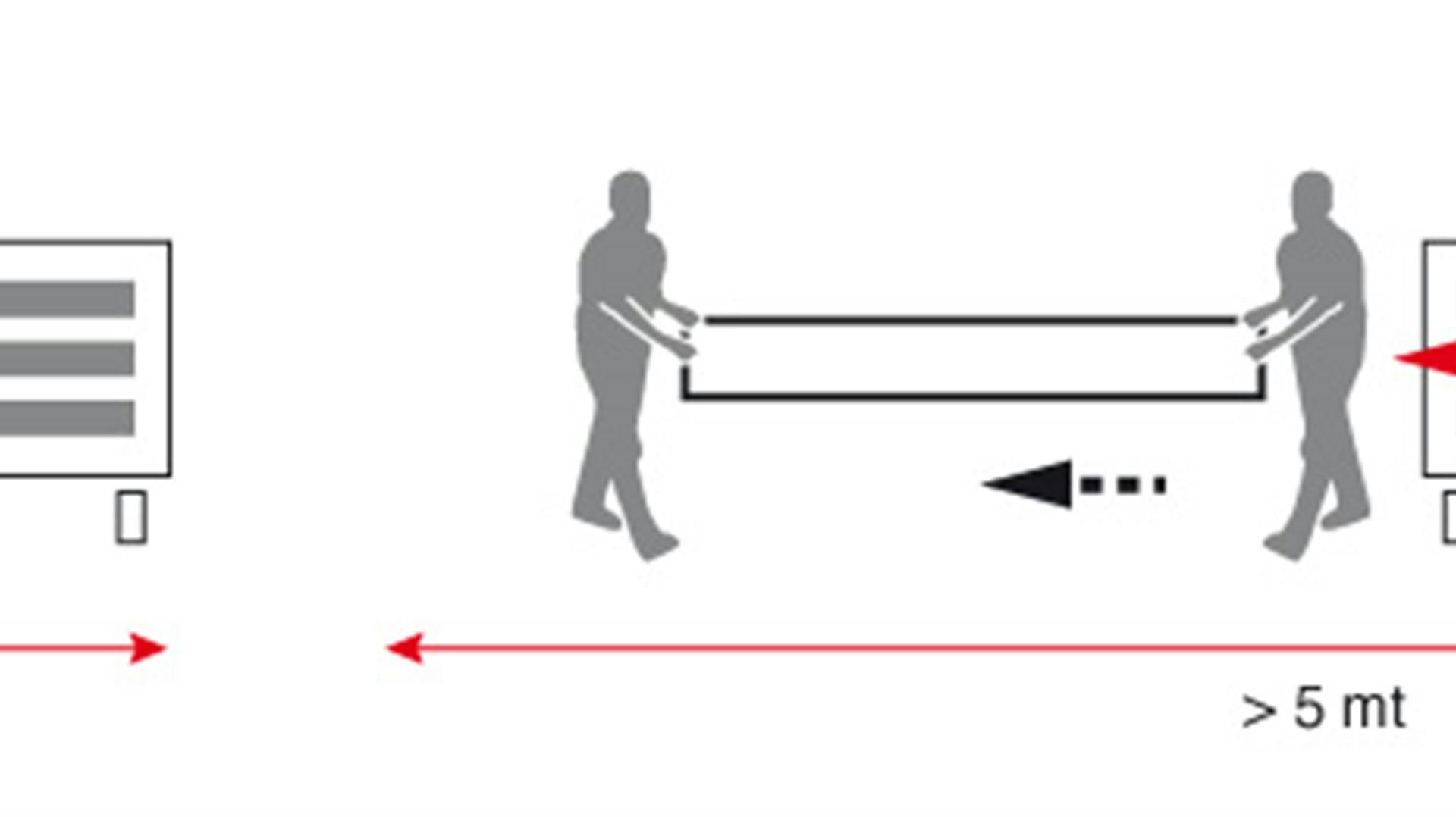

- the removal of the lamps require a free room that is at least double their length (consequently at least 5 m!) and requires two people (see fig.);

IMAGE EXTRACTION COMPETITOR

Removal of the lamp requires a lot of room, plenty of attention, and the presence of two people.

IMAGE EXTRACTION UV RAY

Removal of the UV Ray lamp is very simple and fast.

- vertical applications are more difficult because of their height;

- handling lamps of such length requires great care and attention, as the risk of breaking them is very high. Moreover, their purchase and shipping costs are very high;

- the support structure, significantly cumbersome and complicated, requires complex changes to be made to machine on which it will be applied; in addition, there are very long machine installation and downtimes;

- for different dimensions, a system must be built ad hoc;

- consumption is extremely high, and the entire system requires a considerable installation effort;

- the system always uses the total measure of the lamps, even if the job to be carried out requires smaller measures.