Aluminium printing

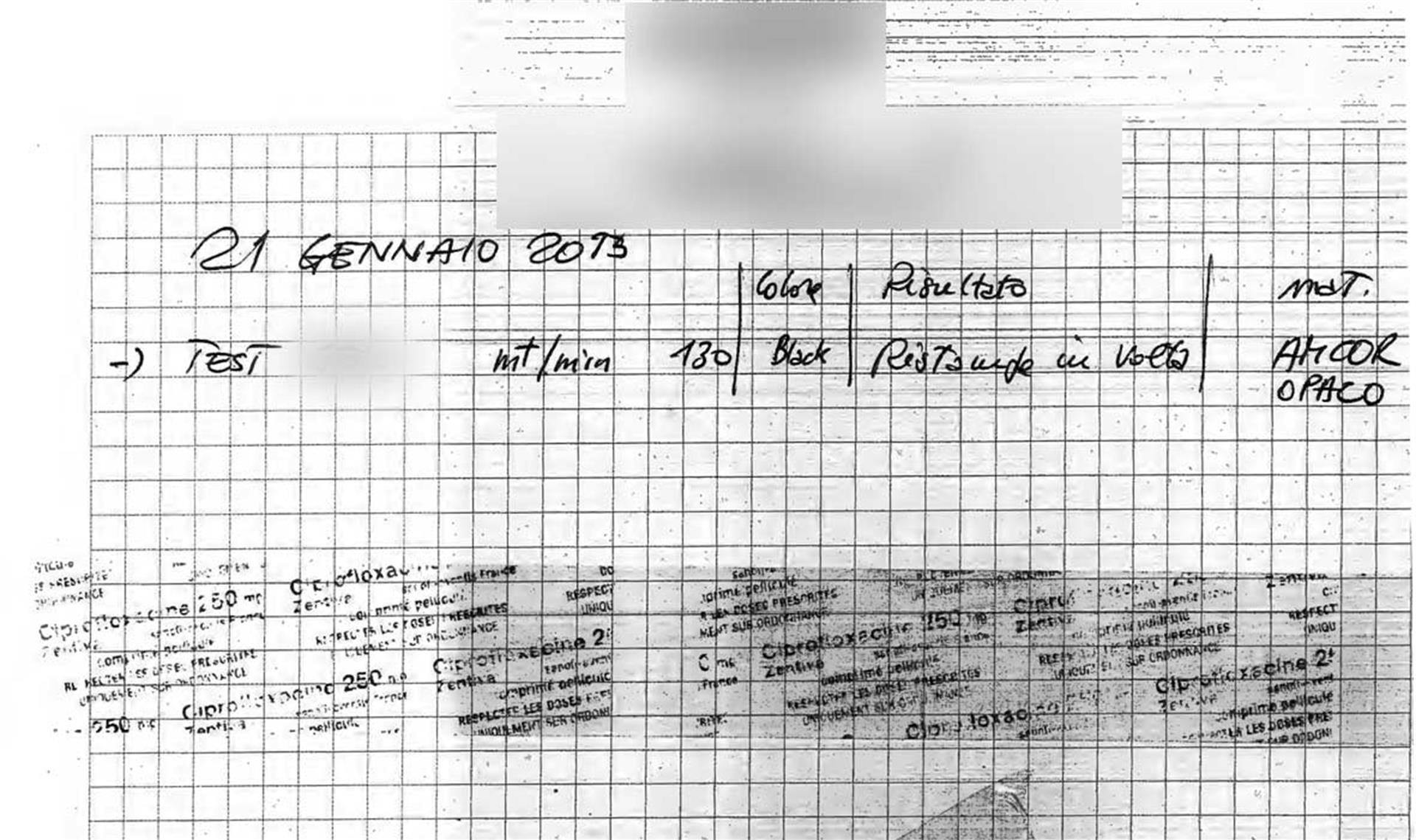

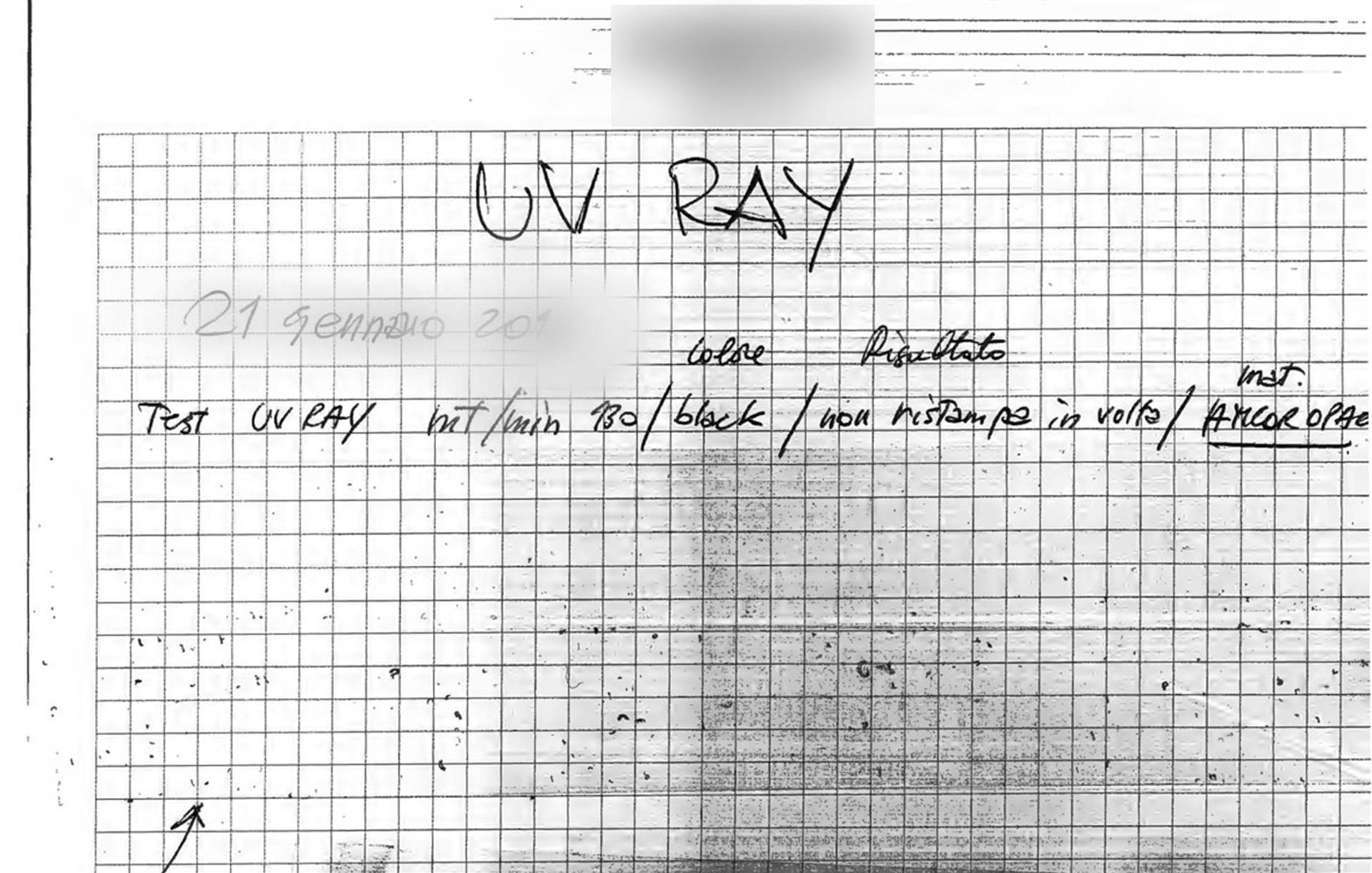

This section, illustrates the result of an aluminium printing test carried out on a flexographic rotary printer, with colour black, on opaque Amcor at 130 m/min..

The sample tests show two completely opposite results: the UV Ray print is perfectly dry while the competitor’s one, when placed in contact with a sheet, releases almost all the ink due to poor anchorage to the media.

In the images, you can see the tests on the UV Ray samples and on those of the competition right after the printing:

IMMAGINE

UV Ray: the ink is perfectly polymerised and anchored.

IMMAGINE

Competition: the ink has no anchorage and sticks to the back of the reel.

Temperatures on intermittent

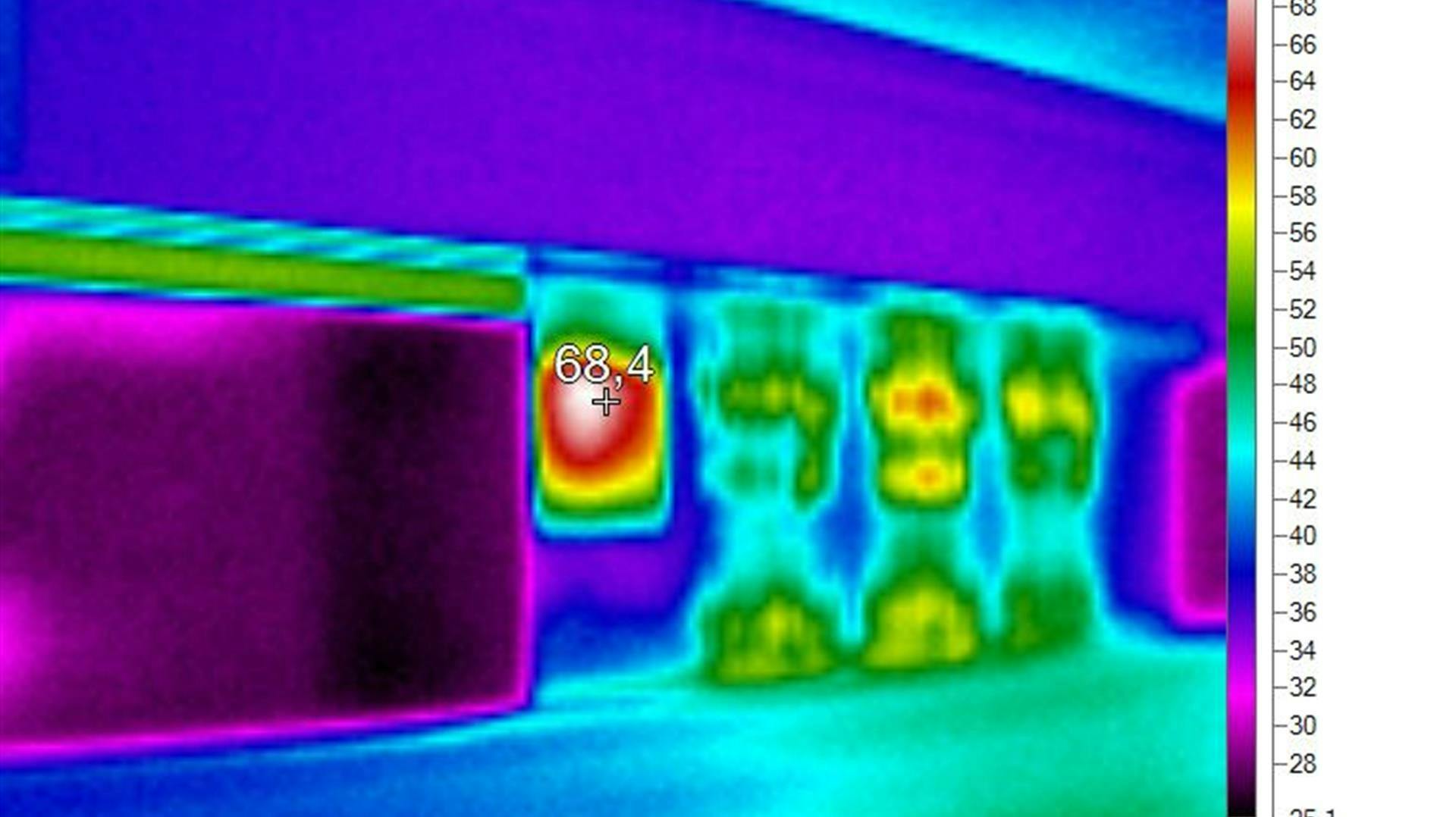

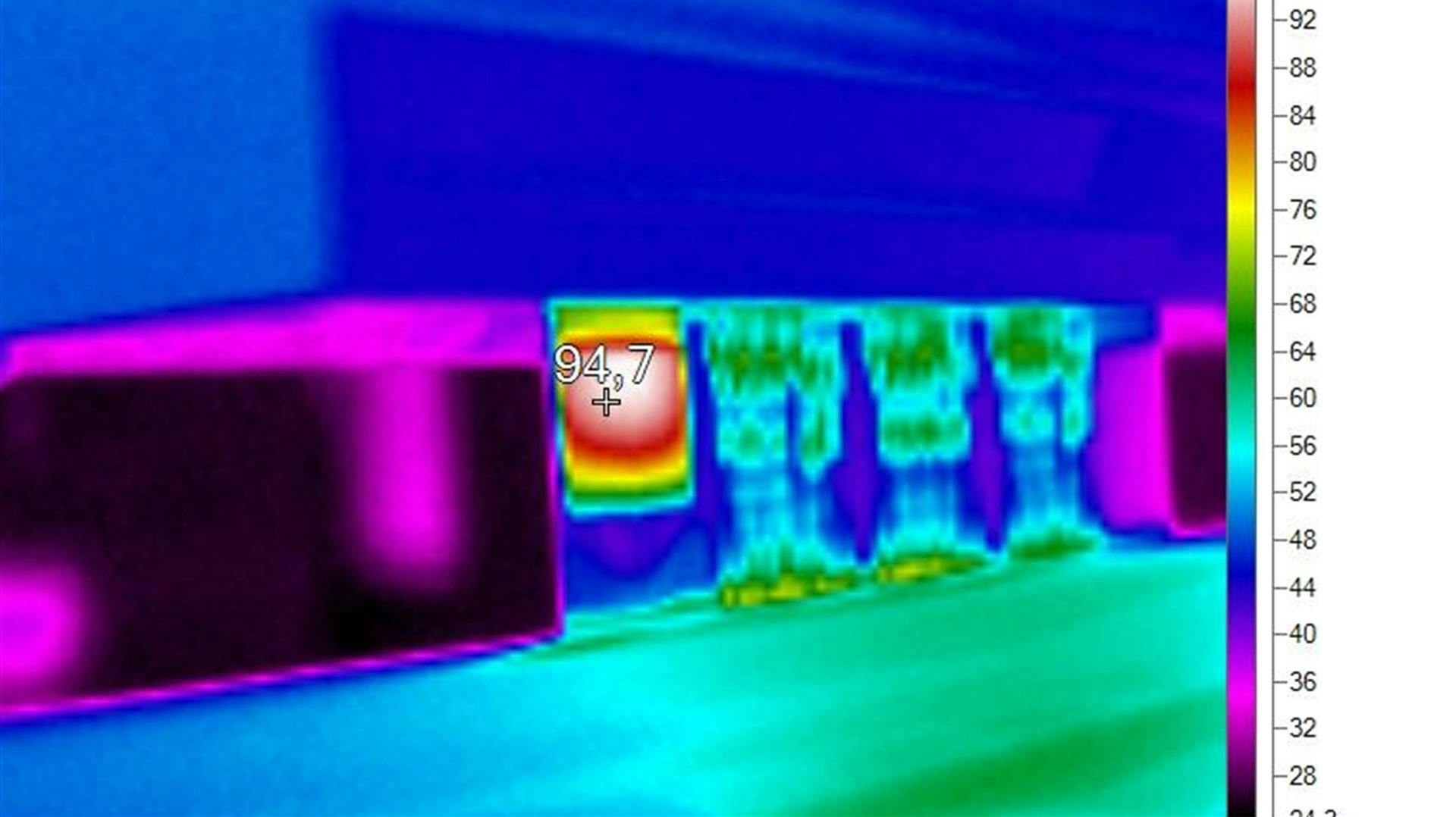

This section, on the other hand, indicates the temperatures measured on an intermittent KBA.

Through an international-brand infrared heat camera, the differences were recorded at various speeds and powers, compared to a competitor’s system:

PowerLinear speedStepTemperature °CUV Ray305 40,3Competitionminimum5 87,4 + additional fan to cool down the media

UV Ray5051° 35,7Competitionminimum51° 61,0UV Ray5052° 68,4Competitionminimum52° 94,7UV Ray5015 35,3UV Ray6015 35,3

IMMAGINE

UV Ray: 50W at 5 m/min, measured 68.4 °C.

IMMAGINE

Competition: minimum power a 5 m/min, measured 94.7 °C.