A new dimension in 3D painting

UV Ray has developed a system dedicated to 3D painting that radically changes what used to be the production line with the competitors’ systems.

Instant results include outstanding energy savings (up to ten times), extremely high polymerisation efficiency, total and capillary control of the production system and, last but not least, a practical and accessible production line.

Here are some characteristics:

- cost of spare parts: the UV Ray systems are totally reliable and, thanks to innovative design and advance engineering, the cost of spare parts is very low;

- utilisation cost: system consumption is extremely reduced, up to ten times compared to the competition; moreover, the extremely high efficiency of the system makes it possible to maintain extremely low temperatures, drastically reducing the energy required to the exchange of hot air in the chamber;

- purchase cost: a UV Ray system does not only have the lowest consumption, installation and management costs compared to other systems, but it costs less too;

- accessible work environment: thanks to the low temperatures of the system, a liveable work environment is created that can be accessed without interrupting production activities;

- remote efficiency control: the system interfaces with a PC from a remote station, from which the efficiency of the system can be monitored and checked without interrupting the work and in conditions of safety;

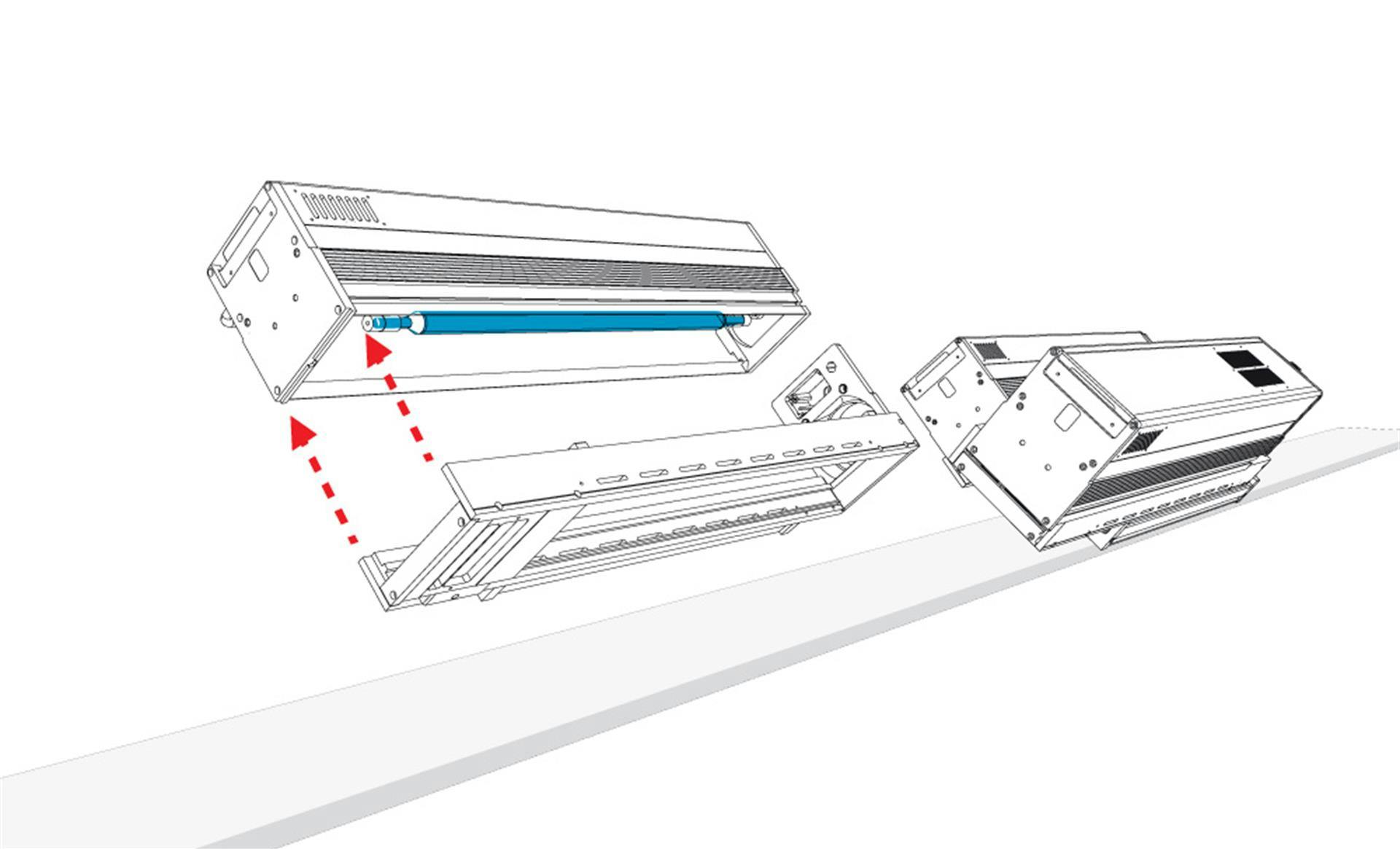

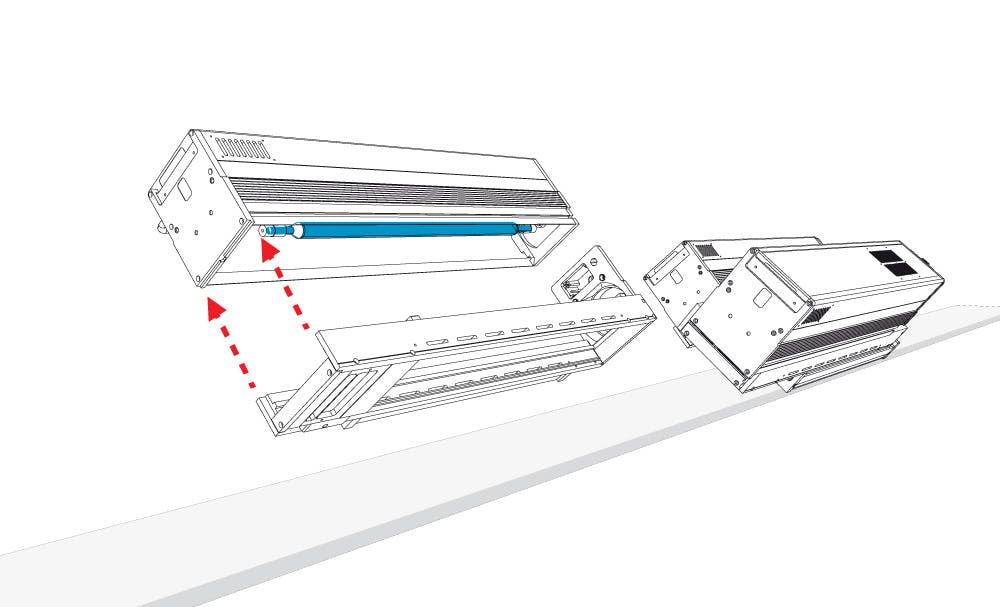

- extremely easy reflector maintenance: the small work spaces, and especially the volumes and structures of the systems. make it difficult to carry out maintenance jobs.

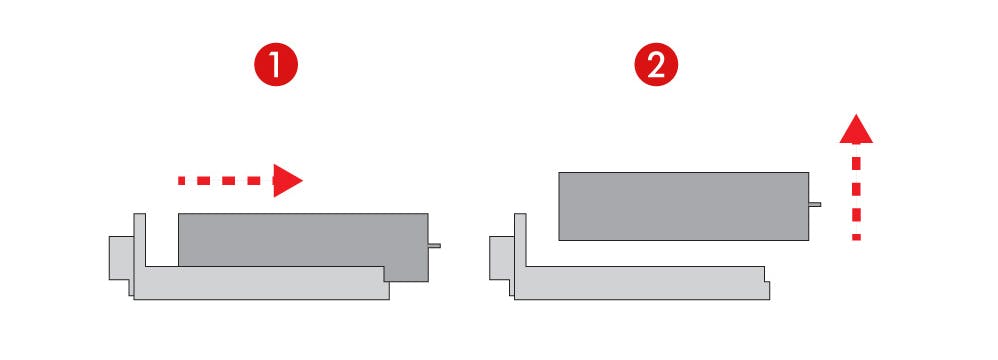

- The UV Ray reflectors, on the other hand, thanks to their compact size, allow the lamp to be removed from its seat with just a few quick movements. Simply release the brakes, allow to slide for a few centimetres and lift: in just a few seconds the lamp group is fully removed.

The two movements needed to remove the lamp.

- This operation can be carried out in the smallest spaces because no manoeuvring room is needed; the operator simply carries out a single vertical movement limited to the height of the lamp.

- UV sensor for efficiency monitoring: the installation of UV sensors in the cab makes it possible to monitor the efficiency of the entire system from a single station, under conditions of safety and without interrupting production. A curtain with pneumatic operation can be installed for sensor protection.

- installation of the reflector protection filter: a glass protects the lamp against any damages caused by objects falling from the line;

- long service life of the lamps: the efficiency and the low operating temperatures allow the lamps to last a very long time.