Seri

Silk Screen Reflector

Based on the Maxwell design, Seri is designed to be installed on a flatbed semi-rotary press for silk screen printing. With an integrated lens, it has low pencil effect on the label and provides high energy density and low power transmission to the web while curing. Available with an air or water cooled base to ensure lower temperature on long print runs.

Thanks to its uniform irradiation diffuser, Seri achieves glossy or matte effects in intermittent silk screen printing machines. With the included infrared filter, Seri can cure Braille, digital ink, heavy solids, and cold foil, all in line.

Silkscreen printing

- True dichroic mirror solution with borosilicate glass, available with multiple coating options for a range of applications

- Robust construction entirely made of extruded aluminum

- 50% better thermal management

- Light arc available up to 2000mm. Solutions with multiple arcs are available for wider applications.

- Fully extractable cassette technology for fast and easy maintenance or lamp replacement (less than 120s)

- Air or water cooled base for stable temperature

- Retrofits available

- Infrared filter installed as standard

- Maximum step printing recommended: 300 mm

- Available with water-based and chill-roll mounting

- Internet remote service with encrypted communication

- MaxLED hybrid option

- Exclusive technology, made in Italy

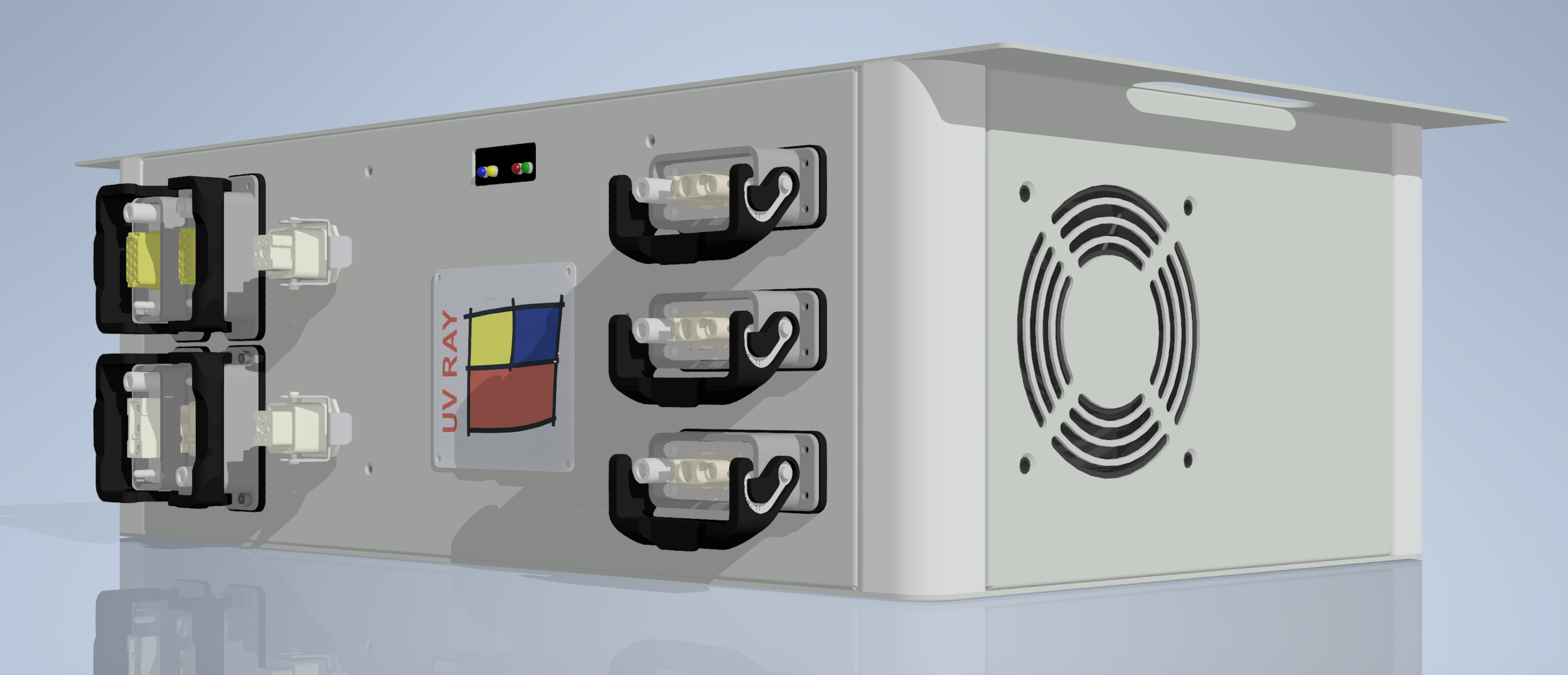

UV Ray’s new PowerMaxx suite of power supplies, engineered in-house and based on 20+ years UV/LED curing experience, offers printers the highest energy efficiency and environmental compatibility in a sleek, compact design to power all UV Ray reflectors and LED lamps.